Program Overview (Available in USA only)

Welcome to the Doosan Robotics Test Drive Program, a unique opportunity to test drive various solutions, such as palletizing, welding, machine tending,

deburring, sanding/polishing, and pick-and-place. This trial program is designed to give you a hands-on experience with our equipment for two weeks.

Available Solutions

-

Palletizers

Paltz CS by beRobox

Paltz CSV by beRobox

PalletizeHD by ONExia

-

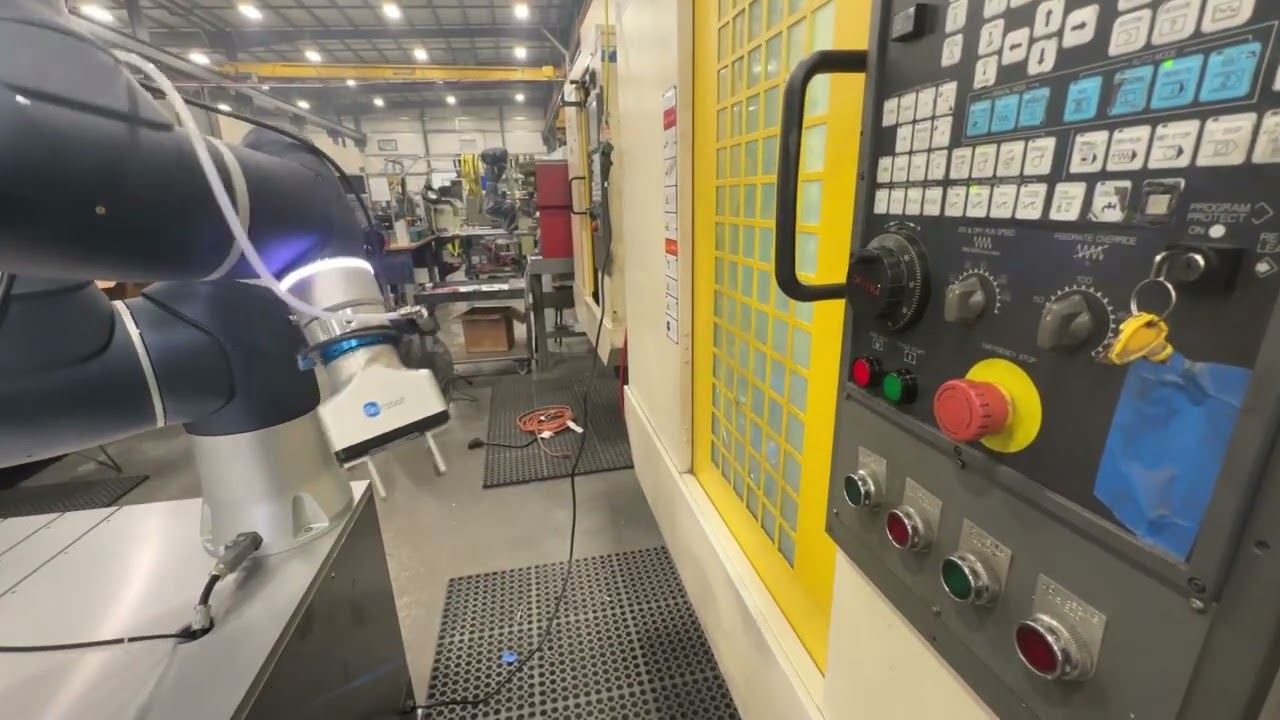

Machine Tending

CNC Tender by Hillside

-

Welding

ArcBoT (standard reach) by CLOOS

ArcBoT (long reach) by CLOOS

ArcBoT (aluminum) by CLOOS

-

Sanding and Polishing

Portable Sanding MC900 by MARI

Portable Sanding MC650 by MARI

Portable pick-and-place MC650 by MARI

-

beRobox Paltz Palletizer

- Plug and Play : Palletizing work cell installs in 5 steps – roll into place, power up, load product, generate pallet pattern, start palletizing.

- Automated Stacking : STACKiT software creates optimal pallet patterns automatically, no programming or calibration needed.

- Versatile Models : Multiple models with varying cycle speeds, payload capabilities, and specialized features for different needs.

- User-Friendly Interface : Intuitive touchscreen and pre-configured control panels simplify operation and troubleshooting.

- Enhanced Safety & Precision : Equipped with pallet locators, product presence sensors, and additional safety measures for reliable and safe operation.

-

ONExia’s PalletizHD palletizing solution

- The "HD" cobot can handle heavy cases with a 40 lb payload.

- Custom end-effector allows for picking multiple lighter cases simultaneously.

- Capable of stacking pallets over 92 inches high.

- Control the system through the embedded touch screen.

- Drag-and-drop software for easy pallet building without programming.

- Save and recall hundreds of pallets for quick changeover with the pallet library.

-

Hillside CNCTender Machine Tending

- User-Friendly Software : Intuitive, no-programming-required setup for quick robot configuration.

- Expertise : Over 30 years in the machine tool industry, meeting modern manufacturing needs.

- Compatibility : Integrates with all major machine tool brands for diverse environments

- Streamlined Integration : Unified hardware and software solution for easy robotic automation transition.

-

Maple Advanced Robotics Inc.

Polishing & Sanding- Autonomous System : Uses AI-driven 3D vision for efficient polishing and sanding on complex surfaces.

- No-Code Programming : Drag-and-drop interface reduces robot setup from days to minutes.

- Hassle-Free Deployment : Plug-and-play installation allows full deployment in less than half a day.

- Production Flexibility : Handles part deviations seamlessly, ensuring consistent quality.

- Cost & Efficiency : Reduces programming time and costs, achieving faster ROI and streamlined processes.

-

CLOOS ArcBoT Welding System

- All-in-One Welding Unit : Compact, portable cobot welding system for versatile production.

- Fast Setup : Requires no prior programming experience, enabling quick start within hours.

- Weaving Patterns : Four pre-configured patterns for consistent, high-quality welds.

- Advanced Safety : Features wire retractions, finger-forced stop, torque sensing, fume extraction, and arc flash protection.

- Complete Package : Includes fixturing table, seam tracking, and touch sensing for high efficiency and quick ROI.

What’s Required?

- Bailment agreement with Doosan Robotics Americas

- Ability to meet installation requirements (power, air, etc.)

- Dedicated staff to train on solution unit and perform required maintenance